Lava stone products: the speciality of Gabri Ceramica

...From the raw material of the volcano god...

The impetuous force of rivers of incandescent lava .... fire in the hands of Hephaestus, the volcano god, who forges a unique material, made of grey-black basaltic rock.... ancient lavas solidified in layers that are deposited on the ground forming Etna's mantle ... the hard work in the quarries to extract this unique stone with its special characteristics of strength and consistency.... The men who work on Mount Etna call this mountain the 'Good Giant', because they have learnt to live with its impetuous fury, which sometimes destroys, but very often gives its delicious fruits and much raw material for the building of the villages that rise along its slopes. At the foot of Europe's highest active volcano, in these huge quarries, work is carried out to extract these large basalt blocks for the processing industry.

...Raw material extraction quarry...

... from extraction to product processing...

This is where the basalt blocks arrive at the sawmill: here the first processing begins, with the squaring of the rocks, their subdivision according to the shape and size obtained, and the classification by consistency and internal compactness of the product. These subdivisions are used to allocate the blocks to specific uses: public building, urban furnishing, private building, furnishing accessories, artistic and decorative production. Only after this classification can the first basic shapes be created to be sold to end users, who sometimes intervene in the sawmill to guide the creation of the blanks according to the uses for which they were designed. Huge machines work day and night to cut and polish the semi-finished products.

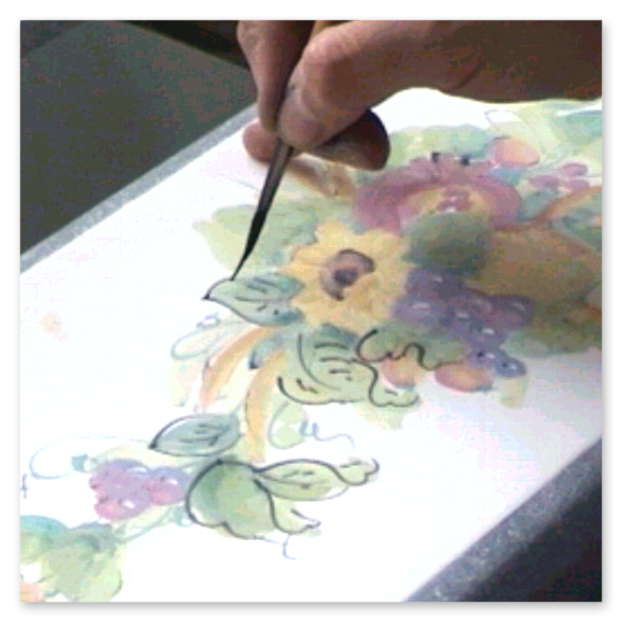

...Freehand expert decorations...

...to the finished product in Italian homes...

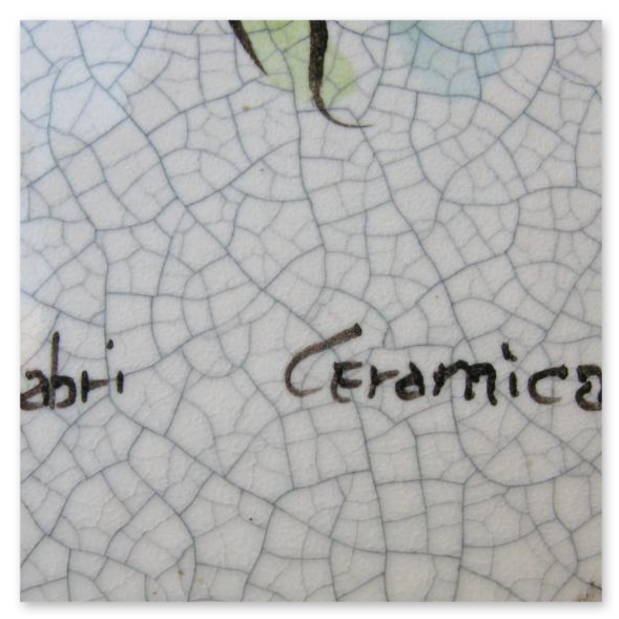

Each artistic design is the result of patient application on the decorating surface, using special colours that are resistant to the high temperatures of the kiln. The designs are then coated with a special vitrifying powder, which will give the decorated top a shiny and transparent appearance after firing. The special high-temperature kiln for ceramising: this stage is also very long and delicate. Gabri Ceramica ensures that everything takes place optimally. Just the slightest change in temperature inside the kiln, in fact, would be enough to nullify entire weeks of careful processing! This, like many others, is the guarantee of Gabri Ceramica's signature quality control. Once the ceramics have been fired in the kiln at temperatures approaching those of the ... God's volcano... the artefact is then cooled, which must be done gradually with a rest phase lasting several hours, leaving the decorated surface inside the firing cavity until it reaches room temperature. Below is a table decorated with drawings of lemons just out of the kiln after the cooling phase, ready to be placed on a wrought-iron pedestal that will complete its creation in a worthy manner. The work of art is thus ready for sale!